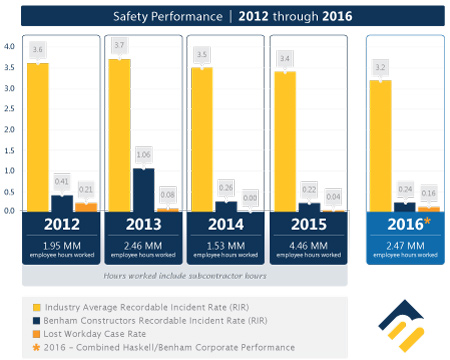

There is no greater measure of safety performance than the security of our staff returning to their homes every day with no injuries. Both Benham and Haskell excel in this metric, exceeding by far the industry average for AEC firms over the past several years. This commitment to safety pervades all activity in our company culture from extensive training to construction planning and site safety protocols. Learn more about how we do it at Haskell.com.

Fundamental to Benham’s culture is the belief that all accidents are preventable. Our corporate safety program is fully integrated into our design and construction planning process, resulting in improved

Like our peers, Benham competes in the market place to secure work. Competitions range from qualification based selection to selections driven by price. Like selection criteria, contract formats preferred by our customers vary widely and include fixed price, cost reimbursable, Construction Management Agency (CMa), Guaranteed Maximum Price (GMP), and hybrids of fixed and reimbursable cost.

We maintain a fully staffed Pre-Construction team to respond to project opportunities including win strategy development and proposal cycle management. During proposal preparation, this team works across multiple organizational elements including:

- Architectural and engineering team members preparing deliverables used in defining project scope

- Coordination with operations in execution planning and project scheduling

- Capital project evaluation, budget analysis, cost estimating

- Coordination with procurement specialist including defining long lead equipment

- Proposal management including assuring compliance with submission requirements

- Contracts review and comment with legal team members

- Senior leadership reviews of work product prior to submission

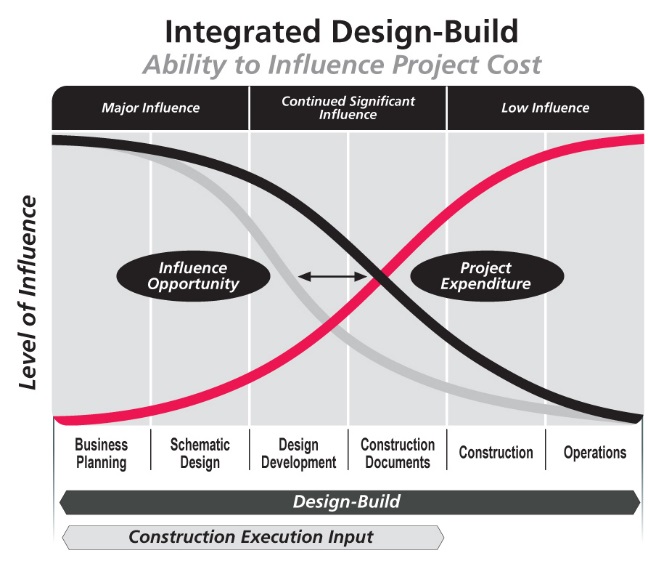

Benham’s in house multidiscipline architecture, facility engineering, industrial engineering, and process engineering professionals provide continuity from the beginning to the end of each project. Self-preforming these services provides us with an opportunity to better control the critical path of each project we construct.

80% of the decisions that influence successful delivery of projects are typically made during design development. Our professionals, preferred subcontractors, and vendors (if applicable) are included in the design process early, defining discrete work packages and timelines for release of design media. This engagement begins with an effective proposal team handoff to executing team members including those that might not have been part of the proposal team. For many years, we have used a process internally called Meeting One to successfully, in a structured environment, make this transition. Our integrated work environment also encourages conversation between design and construction personnel on a daily basis simply due to the collocating of personnel.

Project team meetings include BIM modeling reviews not less than bi-weekly. Construction professionals and key subcontractors are involved in these review meetings and assist the design team members with discipline coordination and construction phasing.

consistency throughout the bid process, bid evaluation and recommendation as well as participation in meetings and negotiations prior to award.

All subcontracts and purchase orders are initiated by our procurement organization and reviewed by the project team prior to issuance for signature. While we deliver these services in a professional and timely manner, we also strive to participate in developing relationships with quality subcontractors and vendors which assist Benham in completing projects that meet quality standards expectation, are completed on time, and exceed financial goals and objectives.

- Seamless organizational delivery captured in the service market image DesignBuildSM

- Less moving parts; Integrated delivery maximizing use of in house engineering and procurement resources

- Maximize use of local and regional subcontractors.

- Only build what we design

Today our DesignBuild operations are housed in four locations; Oklahoma City, St Louis, Tulsa, and Charlotte, NC. Each office is staffed with fulltime personnel in addition to project staff in other localities.

First, design quality control and second, field execution quality control. Each DesignBuild project uses an integrated approach to quality management, engaging engineering and construction professionals in quality reviews for design completeness, discipline engineering coordination, and constructability. Each DesignBuild project receives quality oversight by designated team professionals who are assigned based on experience, training, certifications and specific project requirements.

“Each Benham employee engaged in DesignBuild project execution is expected to identify improvements Benham can make in our QMS program.” - Mike Gwyn, President of Benham