Project Description

- Client:U.S. Army Corps of Engineers, Savannah District

- Location:Robins Air Force Base, Georgia

Robins Air Force Base is the home to more than 60 Air Force units and employs a workforce of more than 25,584 civilians, contractors, and military members. Benham has worked with the U.S. Army Corps of Engineers, Savannah District on multiple projects. Most recently, Benham finished the design, engineering, and construction of two new facilities. The contract was valued at approximately $67 million.

“We could not have been successful without the fantastic cooperation and assistance we received from the Army Corps of Engineers' Robins Air Force Base office."

– Mike Gwyn, President of Benham

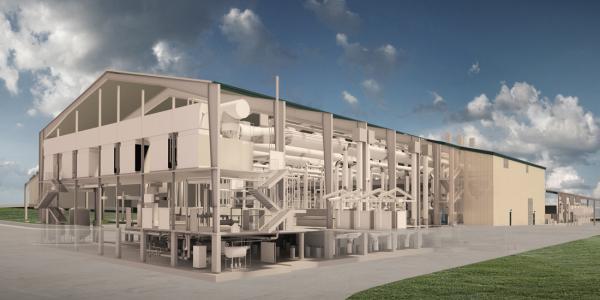

The 29,000-square-foot ground support equipment (GSE) facility will house ground-based equipment including all tools and devices used to support Air Force aircraft operations. The 98,000-square-foot advanced metal finishing facility (AMFF) supports the metal plating processes for several parts of the F-15, C-130, C-17, and C-5 aircraft. The new facility uses energy-efficient materials and was designed and constructed to make working conditions safer, cleaner, and greener for base employees and the environment. Specific energy-efficient, design and construction items included:

• Maximized use of local materials

• Low-flow plumbing fixtures

• Fully insulated facility

• Energy-efficient lights and occupancy sensors

• Use of energy efficient lights and occupancy sensors

• Insulated windows with low e-glass

The AMFF also included the design, engineer, and installation of nine individual metal plating process lines. The plating process lines consist of 163 chemical process tanks, with the largest line containing 20 7,000-gallon tanks. Eight of the process lines are fully automated and will automatically move parts from one process tank to the next, reducing human exposure to the plating chemicals. The nine plating process lines include:

• Aluminum chemical milling, aluminum chromate, anodize

• Chrome plating

• Cadmium and nickel plating

• Stripping, titanium chemical milling, temper etch

• Zinc and manganese phosphate, black oxide

• Passivation and magnesium treatment

• Aluminum preparation and miscellaneous plating

• Electroless nickel and copper plating

• Chemical mill maskant

Other systems installed by Benham at the AMFF include:

• Information and communication systems

• Department of Defense (DoD) Force Protection/Anti-Terrorism Standards (UFC 4-010-01: DoD Minimum Anti-Terrorism Standards for Buildings)

• Fire alarm systems, for both wet and dry fire protections

Awards

• DBIA National Merit Award

• DBIA Southeast Region Industrial Sector Project

• DBIA Southeast Region Public Sector Project over $15 Million

• Sustained Superior Safety Performance Award

DesignBuild is a service mark of Benham in the U.S. and/or other countries.